Powder Coating – AF Azevedos

Thermolacquering is a surface treatment process using electrostatic powder paint.

In order to guarantee maximum efficiency at this stage of production, AF Azevedos has a team specialising in the thermolacquering of ferrous and non-ferrous metal surfaces, thus providing a wide range of solutions for the Construction, Engineering, Architecture, Design and Decoration sectors.

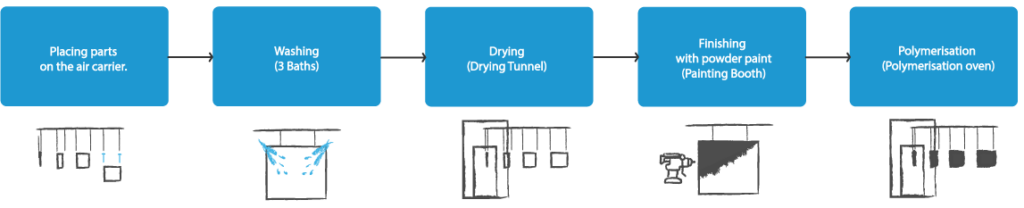

Thermolacquering Process AF Azevedos

The thermolacquering process at AF Azevedos begins when the parts are placed on the overhead conveyor. This is followed by the parts’ pre-treatment process, which consists of three baths: the first bath involves degreasing and phosphating, the second only demineralised water and the final bath is the passivation bath. The parts then pass through the drying tunnel and on to the paint booth. In this both, each part is finished with powder paint, either manually or robotically, in order to provide it with resistance and, in addition, meet the customer’s aesthetic requirements. Finally, the parts are sent to a polymerisation oven, according to the paint specifications, thus completing the lacquering process.

Standard dimensions for lacquering parts:

Until 4000x2000x850mm

What are the advantages of Thermolacquering?

- Greater resistance to external environments, namely UV radiation and corrosion;

- Greater durability and simple maintenance;;

- To meet decorative needs, given the diversity of colours (RAL) and finishes (glossy smooth, matt smooth, textured or embossed) that can be applied.

“Life is a painting, and you are the artist. You have on your palette all the colors in the spectrum…”Paul J. Meyer